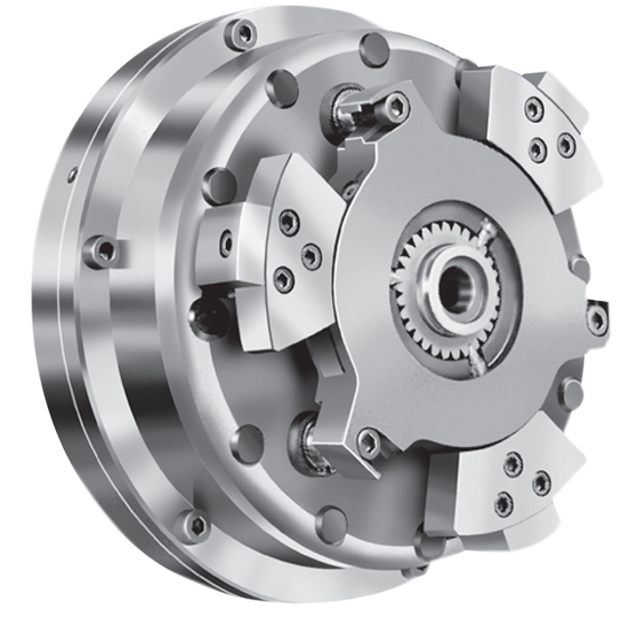

SBL Chuck

Ball-Lock Chucks are Jaw swing type power chucks offering excellent clamping force, rigidity, and durability. Especially, We are designed for not only efficient chucking of cast and forged materials with draft, but also tight holding of overhang.

Work-pieces. Also, we greatly improve roundness of thin walled unfinished work- piece , while accepting complex-shape work-pieces.

Has three-jaw and two-jaw applications. Moreover, long stroke type, large dia thru-hole type, special jaw actuator (base jaw), and newly also available 6 jaw (I.D./ O.D. compatible) as standard.

According to the requirement of the customer, we design and manufacture the fitting portion for machine spindle, top-jaw, and stopper, etc...

- Advantages

- Outside dia. and inside dia. clamping are available with same chuck.

- PULL-BACK function for machining and consistent accuracy.

- Equalizing function of jaws.

- Nam libero tempore, cum soluta nobis est eligendi optio cumque.

- Efficient chucking for heavy-dust cutting of tapered work-piece with minimum holding area.

- Equalizing motion for long life clamping.

Pull Down Chuck

The Pull Down Chuck is O.D. clamping chuck which is suitable for the work-pieces requiring high accuracy (repeatability 0.01 T.I.R.) in squareness and parallelism and also strong clamping force for clamping in secondary operations.

Also, it is very easy to exchange chucking shafts which allows the Pull Down chucks to perform at their full potential for clamping a wide variety of work-pieces.

The material of the body is Ductile Cast-Iron considering anti- abrasion and anti-worn out

Dia Phram Chuck

The Diaphragm Chuck has been used in the machines for scroll machining which are supplied by many machine tool makers as to meet high technical requests.

It is possible to attain high accuracy of concentricity is attained because of elastic accuracy of repeatability from accuracy diaphragm. It is suitable for precise finishing operation because it pull-back the diaphragm law by the arc motion and the elasticity motion according to the uneven of the clamping part improve flatness. parallelism roundness of work-piece .

These chuck are designed with elastic power of repeatability of diaphragm for sale clamping purpose. There is no complicated mechanism causing the trouble and/or losing the power at the portion of friction movement additionally. We don't need to use the grease as these chucks are well scaled and are not influenced by chips and scraps.

PCD Clamping Chuck

The Diaphragm Chuck has been used in the machines for scroll machining which are supplied by many machine tool makers as to meet high technical requests.

It is possible to attain high accuracy of concentricity is attained because of elastic accuracy of repeatability from accuracy diaphragm. It is suitable for precise finishing operation because it pull-back the diaphragm law by the arc motion and the elasticity motion according to the uneven of the clamping part improve flatness. parallelism roundness of work-piece .

These chuck are designed with elastic power of repeatability of diaphragm for sale clamping purpose. There is no complicated mechanism causing the trouble and/or losing the power at the portion of friction movement additionally. We don't need to use the grease as these chucks are well scaled and are not influenced by chips and scraps.

Bavel Gear Chuck

The Bevel Gear chuck is a design power chuck, designed for rough and finish machining or grinding of reverse surface of the gear after standardizing gear surface of bevel gear and pinion gear.

The BG chuck machining accuracy to the gear surface by interchangeable type of gear cages based on 3 kinds of chucks (The Gear Chuck, the face clamp chuck [Jaw escaping type], and the UBL compensating type) in compliance with customer's requests.

The jaws of the BG chuck have floating function and can clamp uniformly the work-piece even if it happens small waving at the surface of work-piece. Exclusive gear cage has two kinds which "pin" method and "all tooth surface" method. As for the pin method, it is cutting chip and dust resistant, and "all tooth surface" method is excellent durability. We are able to grant you your request such as resizing of the chuck, air blow for cutting dust pusher or cage etc ...

- Advantages

- The finger jaws move as circular swing motion which allows to have large opening space and easily clamp inclined portion of the opposite surface of the gear. There is no influence to run-out accuracy that could be caused by one-side clamping.

- As inside of the UG chuck is adopted the ball joint mechanism so less affected by worn-out, and cutting chips and dust do not enter in inside, it is very easy to maintain the UG chuck in good condition. The actuator shaft has been modified to be one body type so the durability is improved more.

- It is still able to use the rotating cylinder and the drawbar of the NC lathe now being used. If you need the air blow from inside, the work-piece pushing function or so, better to ask consult to the machine maker as well.

Face Drive Chuck

Face drivers feature a patented compensating system, operated by a wedge lever, which allows four-pin driving.

This system is highly adjustable and ensures safe and reliable torque transmission under the most difficult conditions; such as rough surfaces or obliqueness of end faces by as much as 3 mm in relation to the rotation axis.

The centre is independent of the driving pins and rests against a Belleville spring washer assembly lodged inside the Morse taper. Even with varying centre sizes, work positioning is maintained with optimal repeatability.

The centre point can be easily removed. There is no need to remove the face driver from the machine tool. The interchange-ability of centres with slots enables turning of work-pieces even with holes in the end piece.

The superior driving efficiency of face drivers means full state of he art performance. Even the most advanced machine tools can be fully exploited.

Face Clamp Chuck

Thin walled, irregular, or out-of-round parts can be clamped for turning, milling and grinding without distortion

Out-of-flat parts can be clamped evenly on all points which will eliminate deformation

Parts can be centralized by collets to positively secure the part or by straight/tapered pins

Jaw quantity and position are designed to clamp the part in the optimum locations , Air sensing capable to ensure that the part is located against the workstop to maintain parallelism

Arbor & Collet Chuck

Arbor and collet chucks are two essential components used in machining and tooling operations, particularly in the field of milling and drilling. They are designed to securely hold cutting tools, such as drills, end mills, and reamers, in place while they rotate at high speeds during machining processes.

An arbor chuck is a device used to mount a cutting tool onto a machine tool, such as a milling machine or drill press. It consists of a cylindrical shaft, typically made of hardened steel, with precision ground surfaces. The precision and rigidity of the arbor chuck are crucial to ensure accurate and stable tool positioning during machining operations.

A collet chuck, on the other hand, is a type of chuck specifically designed to hold cutting tools with a cylindrical shank. It consists of a hollow cylindrical sleeve, typically made of steel or other durable materials, with multiple slits or splits along its length. Collet chucks provide excellent tool concentricity and gripping force, making them suitable for precision machining applications.

Arbor and Collet chucks are indispensable components in machining operations, providing a reliable and secure means of holding cutting tools. Their precision, rigidity, and ability to maintain concentricity are essential for achieving high-quality and accurate results in milling and drilling applications.

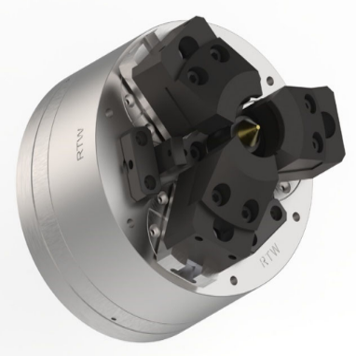

UBL Compensating type chucks

UBL Compensating type chucks, also known as Universal Ball Lock (UBL) chucks, are advanced and versatile workholding devices used in machining and manufacturing processes. These chucks are designed to securely hold and grip various types of cylindrical workpieces, providing precise positioning and stability during machining operations.

The UBL chuck consists of a cylindrical body with a series of evenly spaced radial ball slots and a corresponding number of ball plungers. The workpiece is inserted into the chuck, and the ball plungers engage with the workpiece surface, creating a secure and uniform grip. The radial slots allow for radial displacement of the balls, accommodating variations in workpiece diameter or irregularities.

UBL Compensating chucks offer several advantages in machining operations. First, they provide excellent concentricity and repeatability, ensuring precise machining results and minimizing errors. The compensating capability allows for quick and easy setup, reducing downtime and increasing productivity

UBL Compensating type chucks are advanced workholding devices that offer precise and secure clamping for various workpiece shapes.